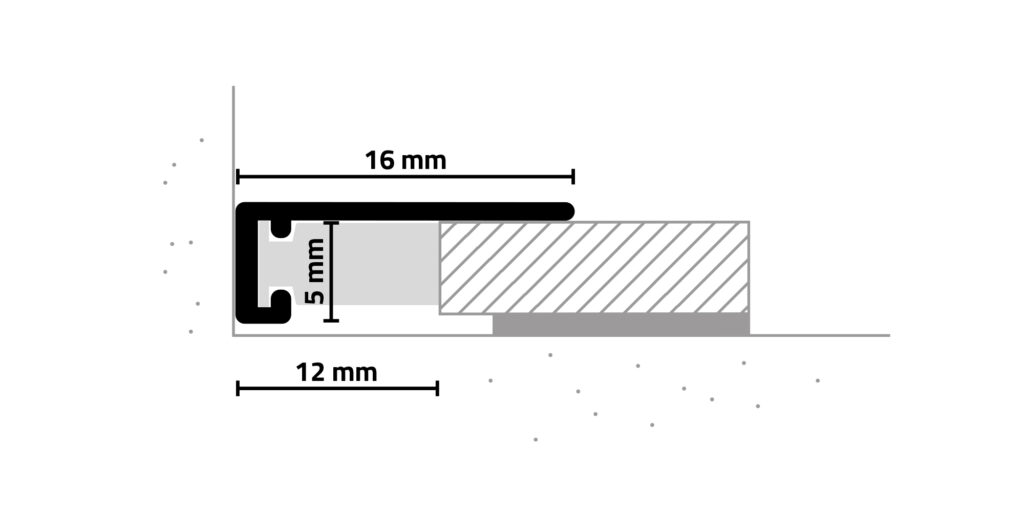

AL16X5

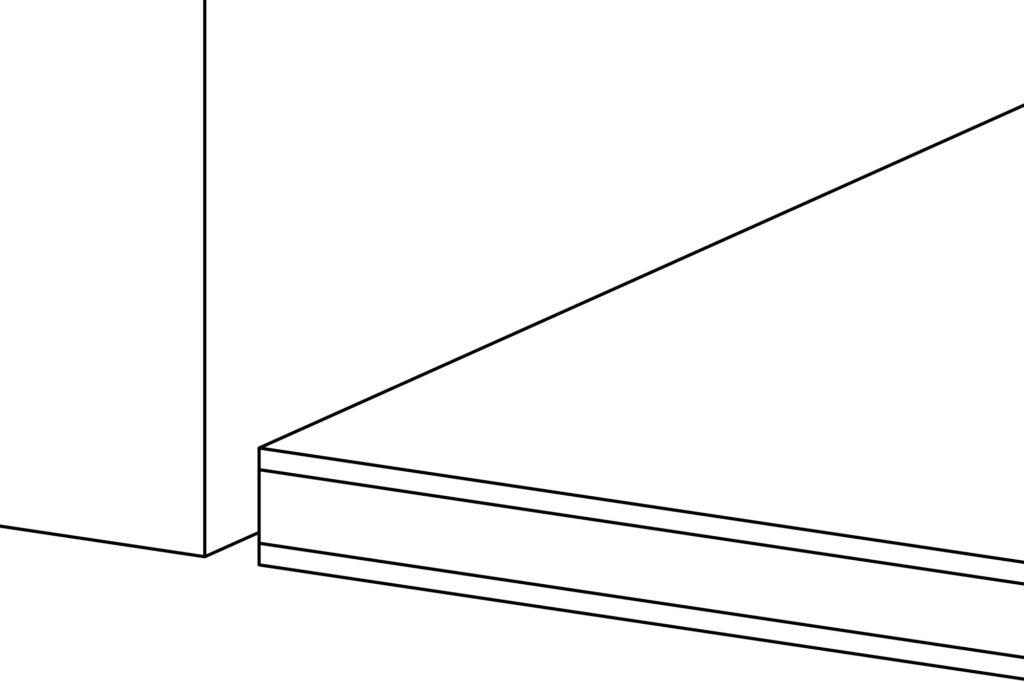

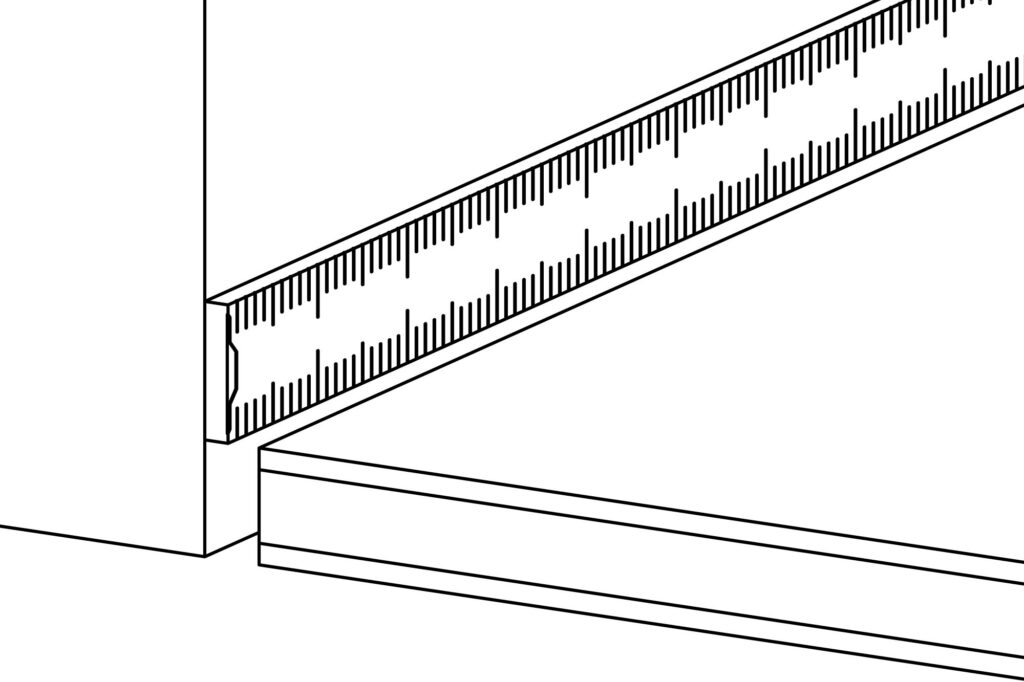

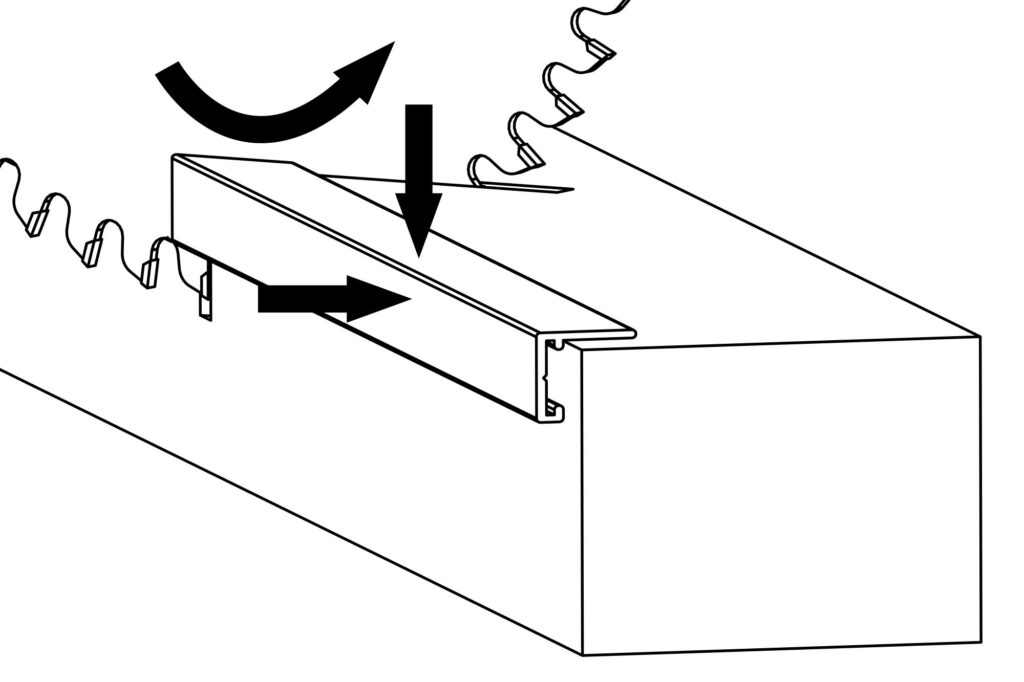

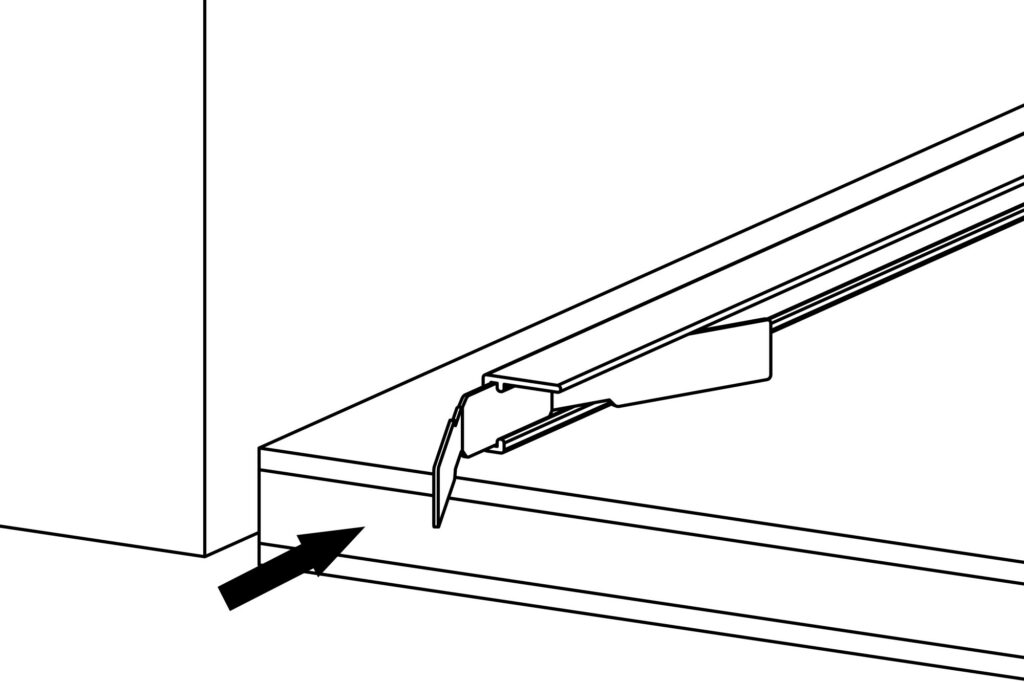

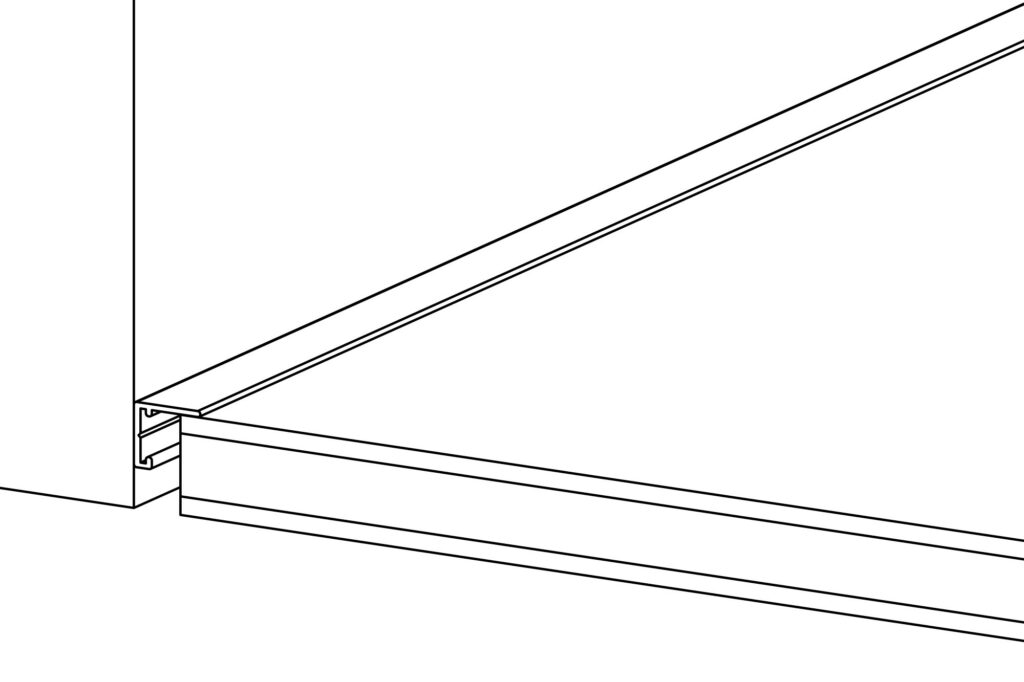

The AL16X5 finishing profile creates a discreet and innovative finish from the floor covering to the wall, window (frame) or stair step – where connection and expansion joints must be maintained structurally

Suitable for:

parquet, laminate, design floors and tiles – from a floor thickness of 5 mm

Prísur: 120 kr/m v/mvg

Gold satin finish EV3

White finely structured RAL 9016

Black satin C35

Titanium satin finish C31

Silver satin finish EV1